Offers high-speed, good follow-up control, and stable material feeding.

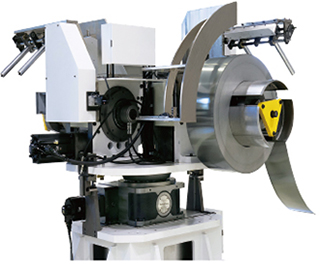

We have a lineup of uncoilers that match various press materials and production conditions, such as EV drive motors, small in-vehicle motors, and separators.

We offer double and single uncoilers and coil masses of 2,000kg to 5,000kg, as well as various options to improve production efficiency, such as automatic coil replacement and material threading.

We offer double and single uncoilers and coil masses of 2,000kg to 5,000kg, as well as various options to improve production efficiency, such as automatic coil replacement and material threading.

VUC Series(6 models)

| VUW300 | VUW550 | VUW650 |

| VUS300 | VUS550 | VUS650 |

| VUS300 | VUS550 | VUS650 |

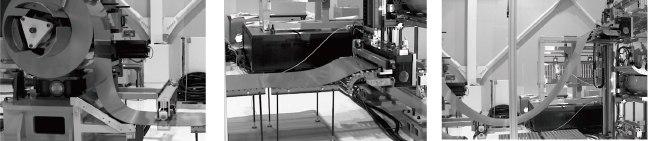

When a coil is attached to the setup side it takes 90 seconds or less to turn it to the production side, automatically insert it into the leveler, and then automatically pass the material through to the feeder.

Specification table

| Item | Unit | VUW(Double) | VUS(Single) | ||||

| VUW300 | VUW550 | VUW650 | VUS300 | VUS550 | VUS650 | ||

| Material width | mm | 50 to 300 | 100 to 550 | 150 to 650 | 50 to 300 | 100 to 550 | 150 to 650 |

| Loadable coil weight | kg | 2,000×2 | 3,000×2 | 5,000×2 | 2,000 | 3,000 | 5,000 |

| Coil inner/outer dia | mm | φ508×φ1200 | φ508×φ1200 | ||||

| Material Thickness | mm | 0.15 to 0.5 | 0.15 to 0.5 | ||||

| Max. Feeding Speed*1 | m/min | 60 | 60 | 80 | 60 | 60 | 80 |

| Product weight | kg | 3,800 | 4,100 | 7,800 | 2,200 | 2,300 | 4,600 |

*1 Feed speed depends on drive motor capacity and reducer.

*2 Please contact us separately regarding follow-up to press start and stop.

*3 The product includes a loop sensor between the uncoiler and loop controller.

*2 Please contact us separately regarding follow-up to press start and stop.

*3 The product includes a loop sensor between the uncoiler and loop controller.

>> OPUS1 Series

High-performance

servo feeder for

stamping presses

servo feeder for

stamping presses

>> OPUS2 Series

Servo feeder ideal for stamping motor cores for home appliances

>> Servo-dex EVR1 Series

An indexing/skewing drive system for rotating the motor cores used for electric motors in automobiles.

>> Servo-dex EVR2 Series

An indexing/skewing drive system for rotating the motor cores used

for electric motors in home

electrical appliances.

>> VG Series

Press feeders

Functionality

Reliability

Functionality

Reliability

>> V Series

Coil feeders for presses

Long Seller

Advanced Functionality

Good Reliability

Long Seller

Advanced Functionality

Good Reliability