World’s best cutter that can cut the thinnest material

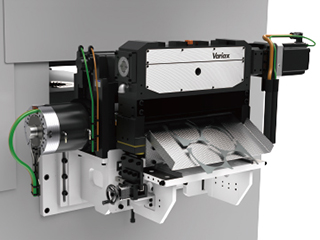

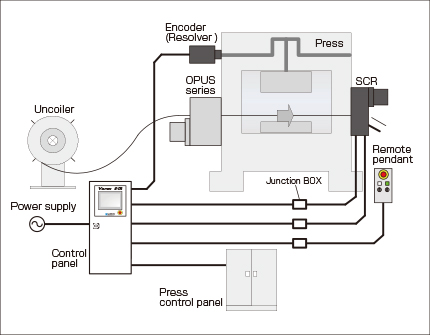

The SCR series is a scrap cutter that uses the thinnest cutter (160 mm) in the world. Since it is the thinnest, it can be installed close to the feeder which reduces problems when transporting skeleton materials for conventional products, making synchronized high-speed press operation possible.

Many problems can occur when you try to speed up the scrap cutting of skeleton materials for a press line. This is because the skeleton material fed from a mold using a Push-Pull feed is not rigid and tends to bend while being transported to the cutter with a feed device. Among possible countermeasures, the most important action to prevent bending is to shorten the distance between the feed device and the cutter, to make it as small as possible. The compact size of this scrap cutter allows it to be installed in close contact with the feeder. Then, using complete synchronization with the press you can achieve stable skeleton cutting of thin plate materials. It also greatly contributes to saving space on the press line.

Many problems can occur when you try to speed up the scrap cutting of skeleton materials for a press line. This is because the skeleton material fed from a mold using a Push-Pull feed is not rigid and tends to bend while being transported to the cutter with a feed device. Among possible countermeasures, the most important action to prevent bending is to shorten the distance between the feed device and the cutter, to make it as small as possible. The compact size of this scrap cutter allows it to be installed in close contact with the feeder. Then, using complete synchronization with the press you can achieve stable skeleton cutting of thin plate materials. It also greatly contributes to saving space on the press line.

SCR1 Series(5 models)

| SCR1-200 | SCR1-300 | SCR1-450 | SCR1-650 | SCR1-800 |

SCR2 Series(5 models)

| SCR2-200 | SCR2-300 | SCR2-450 | SCR2-650 | SCR1-800 |

Compact

Has the world's thinnest cutter (160 mm). Saves space and speeds up press line operations.

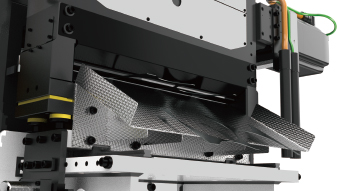

Stable cutting

It offers stable cutting of thin plate materials thanks to its back stopper.

Maintenance

Easy replacement of cutting blades.

A blade can be used on both sides.

A blade can be used on both sides.

Monitoring function

You can check the motor torque on the monitor while cutting (touch panel)

Set up position adjustment

The cutting position can be adjusted.

Specification table

| Item | Unit | SCR1/2 | Remarks | ||||

| -200 | -300 | -450 | -650 | -800 | |||

| Maximum cut material width |

mm | 200 | 300 | 450 | 650 | 800 | |

| 95 | 220 | 345 | 470 | 620 | When installed at an angle of 30° | ||

| 225 | 370 | 515 | 660 | 835 | Cutter blade width | ||

| Material thickness | mm | 0.1~0.5 | |||||

| Cut off load | N | 12,500 | 18,000 | 28,000 | 40,000 | 40,000 | |

| 3,750 | 5,600 | 5,600 | 8,100 | 10,000 | |||

| Synchronized speed | − | 500 | 400 | ||||

| Servo motor | min−1 | SIEMENS/YASKAWA | |||||

| Servo motor | − | N1.5(Black) | |||||

| Mass | kg | 225 | 295 | 350 | 405 | 480 | |

>> OPUS1 Series

High-performance

servo feeder for

stamping presses

servo feeder for

stamping presses

>> OPUS2 Series

Servo feeder ideal for stamping motor cores for home appliances

>> Servo-dex EVR1 Series

An indexing/skewing drive system for rotating the motor cores used for electric motors in automobiles.

>> Servo-dex EVR2 Series

An indexing/skewing drive system for rotating the motor cores used

for electric motors in home

electrical appliances.

>> VG Series

Press feeders

Functionality

Reliability

Functionality

Reliability

>> V Series

Coil feeders for presses

Long Seller

Advanced Functionality

Good Reliability

Long Seller

Advanced Functionality

Good Reliability

>> VGX Series

Coil Feeders for Presses

Fine Tuning during Production

Simple and Precise Parameter Adjustments

Fine Tuning during Production

Simple and Precise Parameter Adjustments

>> VLC/VSC/VZA/VZC Series

Coil Stock Loop Controller

For high-speed feeding.

For high-speed feeding.