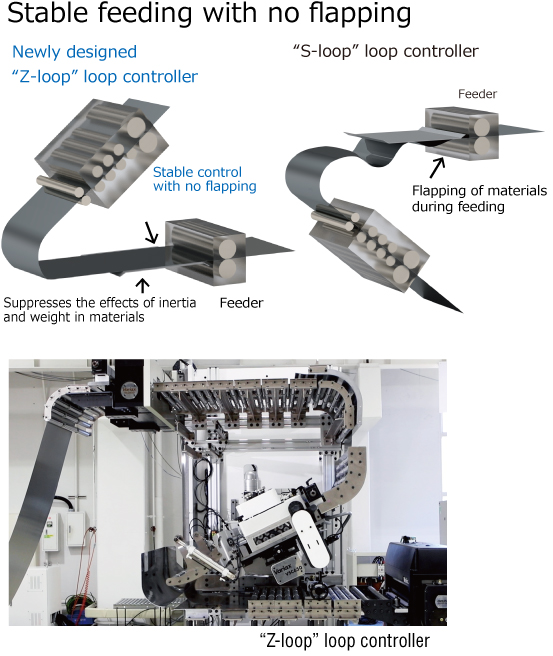

Producing the ideal material loop.

Sankyo developed the NC loop controller in order to create the ideal loop shapes required by the feeding device, using servo technology. This VLC sets up optimum feeding by forming ideal loops in the space allowed, taking advantage of the spring characteristics of materials and stabilizing the loop using a sensor and servo control. The VLC has excellent handling characteristics in that it does not scratch, kink or dent material and can improve both quality and productivity.

The VZA and VZC series are motor cores for EV, and are models compatible with thin and long sheet feeding with a thickness of 0.3 mm or less. The loop shape of the material is less likely to collapse due to the effects of gravity, allowing for stable high-speed feeding.

The VZA and VZC series are motor cores for EV, and are models compatible with thin and long sheet feeding with a thickness of 0.3 mm or less. The loop shape of the material is less likely to collapse due to the effects of gravity, allowing for stable high-speed feeding.

VSC Series(4 models)

| VSC70 | VSC200 | VSC450 | VSC650 |

VZC Series(2 models)

| VZC450 | VZC650 |

VLC Series(4 models)

| VLC50 | VLC200 | VLC450 | VLC650 |

VZA Sereis(2 models)

| VZA450 | VZA650 |

- Employ the high-resolution high-torque servo motor drive.

- To eliminate the bending of the material near the entrance loop.

- Possible to supply-eject the material at creep speed.

- Feed conditions are set by full-color touch screen.

- Integrating a leveler function that corrects the rolling habits of a material.

VSC Series General Specifications

| VLC50 | VLC200 | VLC450 | VLC650 | VSC70 | VSC200 | VSC450 | VSC650 | VZA450 | VZA650 | VZC450 | VZC650 | ||

| Material Thickness | mm | 0~999 | 0.15~0.5 | ||||||||||

| Material Width | mm | 5~50 | 20~200 | 150~450 | 150~650 | 20~70 | 20~200 | 150~450 | 150~650 | 150~450 | 150~650 | 150~450 | 150~650 |

| Max. Feeding Speed | m/min | 150 | 120 | 150 | 120 | 120 | |||||||

| Operating air pressure | MPa | 0.4~0.5 | |||||||||||

| Product weight | kg | 230 | 245 | 716 | 734 | 263 | 295 | 859 | 824 | 2210 | 2380 | 2345 | 2550 |

>> OPUS1 Series

High-performance

servo feeder for

stamping presses

servo feeder for

stamping presses

>> OPUS2 Series

Servo feeder ideal for stamping motor cores for home appliances

>> Servo-dex EVR1 Series

An indexing/skewing drive system for rotating the motor cores used for electric motors in automobiles.

>> Servo-dex EVR2 Series

An indexing/skewing drive system for rotating the motor cores used

for electric motors in home

electrical appliances.

>> VG Series

Press feeders

Functionality

Reliability

Functionality

Reliability

>> V Series

Coil feeders for presses

Long Seller

Advanced Functionality

Good Reliability

Long Seller

Advanced Functionality

Good Reliability