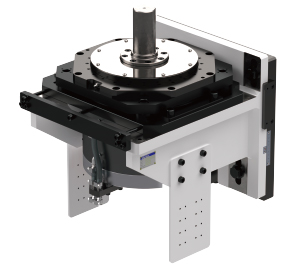

The Servo-dex EVR1 series is an indexing or skewing drive system for rotating the motor core for production lines making motor cores for hybrid, PHEV, and EV car motors.

By connecting a high-performance servo motor directly to the motor core, it can index core stacks with high-speed and high-torque, while allowing you to set the rotation angle freely.

With fusion of a servo motor and a cam motion curve, high speed and a variety rotational stacking build-ups are possible. This contributes to improved productivity of high-quality motor cores.

By connecting a high-performance servo motor directly to the motor core, it can index core stacks with high-speed and high-torque, while allowing you to set the rotation angle freely.

With fusion of a servo motor and a cam motion curve, high speed and a variety rotational stacking build-ups are possible. This contributes to improved productivity of high-quality motor cores.

EVR1 Series(4 models)

| EVR1-230R | EVR1-310R | EVR1-230U |

| EVR1-310U |

| EVR1-310U |

- World-class performance using a high-performance motor

- It also supports arbitrary rotation angle settings, and skew processing of the motor core

- The communication function allows you to check the status of the operation from a remote location

- The combination of a servo driven feeder and a servo-dex device results in maximum motor core line optimization

- Servo tuning automatically adjusts the gain according to the mold’s load.

Specification table

| Item | Units | General specifications | High power specifications | ||

| EVR1-230R | EVR1-310R | EVR1-230U | EVR1-310U | ||

| Rated torque | N・m | 173 | 238 | 453 | 792 |

| Maximum torque | N・m | 538 | 1300 | 643 | 1300 |

| Rated rpm | rpm | 798 | 777 | 823 | 777 |

| Load inertia(max)*2 | kg·m2 | 0.5 | 1.5 | 0.5 | 1.5 |

| Indexing angle | deg | Any angle | |||

| Layout angle | deg | Any angle | |||

| Permitted axial load*3 | N | 100 | |||

| Permitted radial load*4 *5 | N | 2,000 | 4,400 | 2,000 | 4,400 |

| Motor capacity | Kw | 15 | 19 | 39 | 65 |

| Operating air pressure*6 | Mpa | 0.4~0.5 | - | ||

| Required cooling air volume*7 | L/min | 220 | - | ||

| Maximum cooling capacity required | Kw | - | 7.2 | 6.58 | |

| Cooling water volume required | L/min | - | 12.1 | 19.5 | |

| Product weight | kg | 233 | 260 | 233 | 260 |

| *1 | Indicates the accuracy of a single unit. It does not include the residual vibration that occurs when using a timing belt. |

| *2 | The capacity changes, depending on the speed ratio and the load being handled. |

| *3 | Represents the weight of the load. |

| *4 | Represents the load applied to the center height of the output shaft. |

| *5 | Use a timing belt that has a low elastic deformation to suppress residual vibration. |

| *6 | Used for cooling air. |

| *7 | The capacity varies, depending on the amount of cooling air supplied. Cooling air is supplied when the motor temperature reaches 60˚C or higher. |

>> OPUS1 Series

High-performance

servo feeder for

stamping presses

servo feeder for

stamping presses

>> OPUS2 Series

Servo feeder ideal for stamping motor cores for home appliances

>> Servo-dex EVR2 Series

An indexing/skewing drive system for rotating the motor cores used

for electric motors in home

electrical appliances.

>> VG Series

Coil feeders for presses

Advanced functionality

Reliability

Advanced functionality

Reliability

>> V Series

Coil feeders for presses

Long Seller

Advanced Functionality

Good Reliability

Long Seller

Advanced Functionality

Good Reliability

>> VGX Series

Coil Feeders for Presses

Fine Tuning during Production

Simple and Precise Parameter Adjustments

Fine Tuning during Production

Simple and Precise Parameter Adjustments