Servo-controlled rotating-core building device is an improvement from the previous mechanical rotating-core building device.

Any angle of rotation can be set freely.

Any angle of rotation can be set freely.

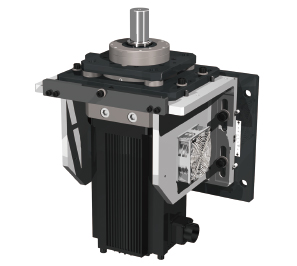

The Servo-dex EVR2 series is an indexing/skewing drive system for rotating the electric motor cores used in home appliances. It is optimal for electric motor core production press lines that make motors for home appliances, such as air conditioners and small motors for automobiles.

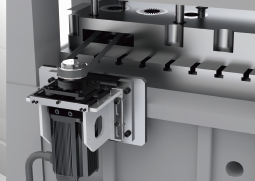

It reduces mold maintenance by suppressing vibration when stopping a workpiece with high-precision positioning.

This series can easily be controlled using a timing signal, and various control patterns are now also available.

It reduces mold maintenance by suppressing vibration when stopping a workpiece with high-precision positioning.

This series can easily be controlled using a timing signal, and various control patterns are now also available.

EVR2 Series(3 models)

| EVR2-75 | EVR2-150 | EVR2-300 |

- Supports optional stacking angle settings and various types of control patterns

- Stacking operation triggered by the timing signal

- Its high precision positioning increases mold life.

- The combination of a servo driven feeder and a servodex device results in maximum motor core line optimization

Specification table

| Item | Units | EVR2-75 | EVR2-150 | EVR2-300 |

| Rated torque | N・m | 48 | 95 | 358 |

| Maximum torque | N・m | 119 | 224 | 752 |

| Rated rpm | rpm | 1500 | 1500 | 800 |

| Load inertia(max)*1 | kg·m2 | 0.05 | 0.15 | 1.25 |

| Indexing angle | deg | Any angle | ||

| Permitted axial load | deg | Any angle | ||

| Permitted axial load)*3 | N | 100 | ||

| Permitted radial load*4 *5 | N | 2,000 | 3,000 | 4,000 |

| Motor capacity | Kw | 7.5 | 15 | 30 |

| Product weight | kg | 128 | 217 | 450 |

| *1 | Indicates the accuracy of a single unit. It does not include the residual vibration that occurs when using a timing belt. |

| *2 | The capacity changes, depending on the speed ratio and the load being handled. |

| *3 | Represents the weight of the load. |

| *4 | Represents the load applied to the center height of the output shaft. |

| *5 | Use a timing belt that has a low elastic deformation to suppress residual vibration. |

>> Servo-dex EVR1 Series

An indexing/skewing drive system for rotating the motor cores used for electric motors in automobiles.

>> OPUS1 Series

High-performance

servo feeder for

stamping presses

servo feeder for

stamping presses

>> OPUS2 Series

Servo feeder ideal for stamping motor cores for home appliances

>> VG Series

Coil feeders for presses

Advanced functionality

Reliability

Advanced functionality

Reliability

>> V Series

Coil feeders for presses

Long Seller

Advanced Functionality

Good Reliability

Long Seller

Advanced Functionality

Good Reliability

>> VGX Series

Coil Feeders for Presses

Fine Tuning during Production

Simple and Precise Parameter Adjustments

Fine Tuning during Production

Simple and Precise Parameter Adjustments