The Ultimate Servo Feeder

The Variax OPUS1 series is a high-performance servo feeder that is optimal for use in motor core production lines for hybrid, PHEV, and EV car motors.

By integrating a high capacity servo motor and roll into one body, it achieves world-class performance.

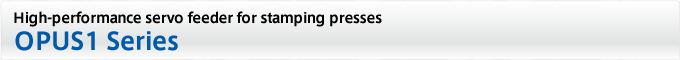

The driving servomotor is operated according to a unique cam curve.

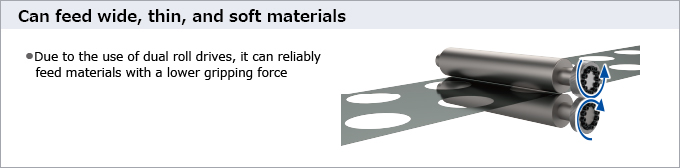

Servomotor and cam curves are also used to control vertical roll motion and the release mechanism, allowing the OPUS series to feed thin and soft materials.

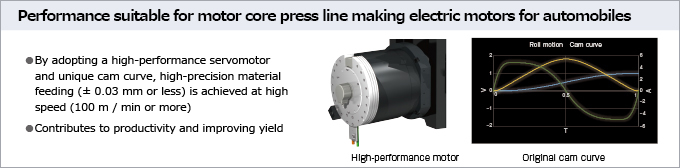

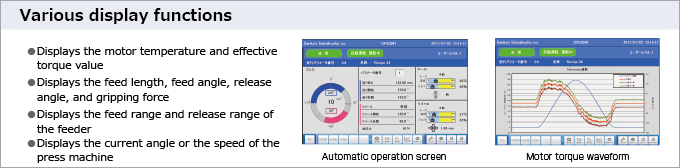

The OPUS series control system is also equipped with a monitor function, diagnostic function, anda large monitor. Its communication function makes it possible to check the operation from a remote location. This combination greatly improves its operability.

By integrating a high capacity servo motor and roll into one body, it achieves world-class performance.

The driving servomotor is operated according to a unique cam curve.

Servomotor and cam curves are also used to control vertical roll motion and the release mechanism, allowing the OPUS series to feed thin and soft materials.

The OPUS series control system is also equipped with a monitor function, diagnostic function, anda large monitor. Its communication function makes it possible to check the operation from a remote location. This combination greatly improves its operability.

OPUS1 Series(4 models)

| OPUS1-200 | OPUS1-300 | OPUS1-450 | OPUS1-650 |

- High-end model combining high speed, high precision and multiple functions

- The communication function allows you to check the status of the operation from a remote location

- Excellent operability with a security system

- Various display functions

- Global support for many languages, standards, and services

- Can feed wide, thin, and soft materials

Motor core line for electric motors used in automobiles

Control configuration diagram

Specification table

| Model name | Units | OPUS1-200 | OPUS1-300 | OPUS1-450 | OPUS1-650 | OPUS1R-500X | OPUS1R-750X |

| Feed Length | mm | 1-200(999) | 1-300(999) | 1-450(999) | 1-650(999) | 1-500(999) | 1-750(999) |

| Material thickness | mm | max 2 | max 5 (4.7)*6 | ||||

| Material Width | mm | max 200 | max 300 | max 450 | max 650 | max 500 | max 750 |

| Grip Force | N | 1,500~3,000 | 3,000~5,000 | 3000~5000 | |||

| Max. Strokes | min-1 | 1,000 | 500 | 500 (300)*7 | |||

| Max. Feeding Speed |

m/min |

Standard air-cooled motor: up to 70 m/min*1 Standard water-cooled motor: 70 m/min, or more*1*3*4 Water-cooled high power motor: 80 m/min, or more*1*3*4 |

Standard air-cooled motor: up to 100 m/min*1 Standard water-cooled motor: 100 m/min, or more*1*3*4 Water-cooled high power motor: 120 m/min, or more*1*3*4 |

Water-cooled high power motor: 120 m/min, or more *1*3*4 |

|||

| Repeat Accuracy | mm | ±0.03*2 | |||||

| Air consumption | ℓ/min | 200*4 | − | ||||

| Operating air pressure | MPa | 0.5~0.6 | |||||

| Product weight | kg | 220 | 240 | 415 | 480 | 440 | 535 |

*1 Please check the separate feed capacity diagram.

*2 The feed precision depends on the operating conditions. The values given here are for reference purposes only.

*3 Maximum feed rate when a water-cooled motor is used.

*4 If the motor is water cooled, you will need to prepare your own cooling system (chiller) and hoses.

*5 The amount of air used for an air-cooled motor. (The feed capacity depends on the amount of cooling air supplied.)

*6 If the pilot release amount is 1.0, the upper limit for the material thickness will be 4.7 mm.

*7 When the pilot release amount is 1.0 mm, the maximum press speed will be 300 min-1.

*2 The feed precision depends on the operating conditions. The values given here are for reference purposes only.

*3 Maximum feed rate when a water-cooled motor is used.

*4 If the motor is water cooled, you will need to prepare your own cooling system (chiller) and hoses.

*5 The amount of air used for an air-cooled motor. (The feed capacity depends on the amount of cooling air supplied.)

*6 If the pilot release amount is 1.0, the upper limit for the material thickness will be 4.7 mm.

*7 When the pilot release amount is 1.0 mm, the maximum press speed will be 300 min-1.

>> OPUS2 Series

Servo feeder ideal for stamping motor cores for home appliances

>> Servo-dex EVR1 Series

An indexing/skewing drive system for rotating the motor cores used for electric motors in automobiles.

>> Servo-dex EVR2 Series

An indexing/skewing drive system for rotating the motor cores used

for electric motors in home

electrical appliances.

>> VG Series

Coil feeders for presses

Advanced functionality

Reliability

Advanced functionality

Reliability

>> V Series

Coil feeders for presses

Long Seller

Advanced Functionality

Good Reliability

Long Seller

Advanced Functionality

Good Reliability

>> VGX Series

Coil Feeders for Presses

Fine Tuning during Production

Simple and Precise Parameter Adjustments

Fine Tuning during Production

Simple and Precise Parameter Adjustments