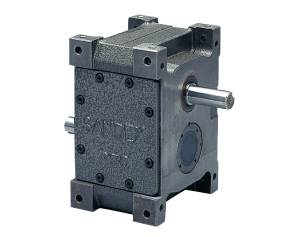

The Parallel Index/P Series uses a parallel cam mechanism with parallel input and output shafts. Because it is easy to produce drives with any arbitrary small number of stops (e.g. 1, 2, or 3), the P Series is suitable for conveyors with long feed pitches.

Parallel Shaft Type

Unlike other SANDEX indexers, the input and output shafts on a P Series indexer are parallel.

Wide Product Lineup

Available in many sizes and indexing configurations.

Suitable for a Small Number of Stops.

Units can be made from one indexing stop.

Flexible Mounting Positions

Index mounts in any position with gearmotor mounting on either side of the index.

- Cardboard forming machines

- Cigarette wrapping machines

- Food filling and wrapping machines

- Drive unit for various types of conveyors

P Series Specifications

| Description | Symbol | Unit | P40/E40 | P50/E50 | P65/E65 | P80/E80 | P100/E100 | P125/E125 |

| P - Indexing Stops | s | 1, 2, 3, 4, 6, 8 | ||||||

| E - Oscillating Angle | φ | deg | 15, 30, 45 | |||||

| Indexes per Minute | ipm | 0 to 300 | ||||||

| Standard Cam Curve | Modified Sine (MS), Modified Constant Velocity (MCV) | |||||||

| Output Allowable Thrust Load | P1 | N | 637 | 1274 | 2450 | 3528 | 4704 | 5096 |

| Output Allowable Radial Load | P2 | N | 490 | 980 | 1568 | 2450 | 3920 | 6174 |

| Output Static Torque | Ts | N・m | Refer to Torque Transfer Table | |||||

| Output Torsional Rigidity | K1 | N・m/rad | 2.0×103 | 4.3×103 | 9.0×103 | 1.81×104 | 3.19×104 | 4.93×104 |

| Output Moment of Inertia | J0 | kg・m2 | Refer to Torque Transfer Table | |||||

| Input Allowable Thrust Load | P4 | N | 637 | 1274 | 2450 | 3528 | 4704 | 5096 |

| Input Max Repetitious Bending Force | P5 | N | 490 | 980 | 1568 | 2450 | 3920 | 6174 |

| Input Max Repetitious Allowable Torque | P6 | N・m | 29.4 | 58.8 | 107.8 | 245 | 392 | 637 |

| Input Torsional Rigidity | K2 | N・m/rad | 2.0×103 | 4.3×103 | 9.0×103 | 1.81×104 | 3.19×104 | 4.93×104 |

| Input Moment of Inertia (Note 1) | J1 | kg・m2 | 1.5×10-4 | 2.75×10-4 | 8.25×10-4 | 2.45×10-3 | 6.0×10-3 | 1.63×10-2 |

| Indexing Accuracy (1 Dwell) (1, 2, 3, 4 stops) |

sec | ±90 | ±72 | ±60 | ±60 | ±60 | ±60 | |

| Indexing Accuracy (2 Dwell) (6, 8 stops) |

sec | ±180 | ±144 | ±120 | ±120 | ±120 | ±120 | |

| Repeatability | sec | 90 | 72 | 60 | 60 | 60 | 60 | |

| Product Weight | kg | Approx. 3.5 | Approx. 7.5 | Approx. 14 | Approx. 20 | Approx. 36 | Approx. 65 | |

| Housing Color | Hammer net gray | |||||||

| Lubrication | Grease lubrication | Grease lubrication | Oil lubrication | Oil lubrication | Oil lubrication | Oil lubrication | ||

| Output Configuration | Shaft | Shaft | Shaft | Shaft | Shaft | Shaft | ||

Note 1) Input moment of inertia: J is calculated in dwell.

| Description | Symbol | Unit | P150/E150 | P175/E175 | P200/E200 | P250/E250 | P320/E320 | P400/E400 |

| P - Indexing Stops | s | 1, 2, 3, 4, 6, 8 | ||||||

| E - Oscillating Angle | φ | deg | 15, 30, 45 | |||||

| Indexes per Minute | ipm | 0 to 300 | ||||||

| Standard Cam Curve | Modified Sine (MS), Modified Constant Velocity (MCV) | |||||||

| Output Allowable Thrust Load | P1 | N | 7350 | 9016 | 12936 | 15190 | 22540 | 26460 |

| Output Allowable Radial Load | P2 | N | 8428 | 9800 | 13524 | 15288 | 23520 | 39200 |

| Output Static Torque | Ts | N・m | Refer to Torque Transfer Table | |||||

| Output Torsional Rigidity | K1 | N・m/rad | 1.23×105 | 1.65×105 | 3.19×105 | 5.26×105 | 1.08×106 | 1.46×106 |

| Output Moment of Inertia | J0 | kg・m2 | Refer to Torque Transfer Table | |||||

| Input Allowable Thrust Load | P4 | N | 7350 | 9016 | 12936 | 15190 | 22540 | 26460 |

| Input Max Repetitious Bending Force | P5 | N | 8624 | 9800 | 18620 | 23520 | 41160 | 54880 |

| Input Max Repetitious Allowable Torque | P6 | N・m | 1323 | 1813 | 3136 | 4900 | 10780 | 14700 |

| Input Torsional Rigidity | K2 | N・m/rad | 1.76×105 | 1.65×105 | 3.19×105 | 5.26×105 | 1.08×106 | 1.46×106 |

| Input Moment of Inertia (Note 1) | J1 | kg・m2 | 4.0×10-2 | 7.5×10-2 | 0.148 | 0.495 | 1.7 | 4.43 |

| Indexing Accuracy (1 Dwell) (1, 2, 3, 4 stops) |

sec | ±60 | ±60 | ±60 | ±60 | ±60 | ±60 | |

| Indexing Accuracy (2 Dwell) (6, 8 stops) |

sec | ±120 | ±120 | ±120 | ±120 | ±120 | ±120 | |

| Repeatability | sec | 60 | 60 | 60 | 60 | 60 | 60 | |

| Product Weight | kg | Approx. 100 | Approx. 160 | Approx. 220 | Approx. 350 | Approx. 750 | Approx. 1400 | |

| Housing Color | Hammer net gray | |||||||

| Lubrication | Oil lubrication | Oil lubrication | Oil lubrication | Oil lubrication | Oil lubrication | Oil lubrication | ||

| Output Configuration | Shaft | Shaft | Shaft | Shaft | Shaft | Shaft | ||

Note 1) Input moment of inertia: J is calculated in dwell.

Options for the P Series

| Item | Model | P40/E40 | P50/E50 | P65/E65 | P80/E80 | P100/E100 | P125/E125 | |

| Mounted Reducer | R type | Special | R48 | R48 | R48, R65 | R65, R80 | R80 | |

| Mounted Cam Balancer | B type | Special | Special | Special | Special | Special | Special | |

| Mounted TorqueLimiter | TF and TC types | 4, 5 | 6 | 6 | 6, 7 | 7, 8 | 7, 8 | |

| Mounted Torque Limit Overload Sensor | Available | Available | Available | Available | Available | Available | ||

| Mounted Motor | Special | Special | Special | Special | Special | Special | ||

| Mounted Timing Cam | Special | Special | Special | Special | Special | Special | ||

| Different Oil Fill/Drain Position | - | - | Available | Available | Available | Available | ||

| Knock Pin Holes in Housing | Available | Available | Available | Available | Available | Available | ||

| Different Input/Output Shaft Configuration | Available | Available | Available | Available | Available | Available | ||

Special: Contact for further details.

| Item | Model | P150/E150 | P175/E175 | P200/E200 | P250/E250 | P320/E320 | P400/E400 | |

| Mounted Reducer | R type | R80, R100 | R100 | R100, R125 | R125, R160 | R160 | R48, R65 | |

| Mounted Cam Balancer | B type | Special | Special | Special | Special | Special | Special | |

| Mounted TorqueLimiter | TF and TC types | 8, 11 | 11, 14 | 11, 14 | 14, 18 | 18 | 6, 7 | |

| Mounted Torque Limit Overload Sensor | Available | Available | Available | Available | Available | Available | ||

| Mounted Motor | Special | Special | Special | Special | Special | Special | ||

| Mounted Timing Cam | Special | Special | Special | Special | Special | Special | ||

| Different Oil Fill/Drain Position | Available | Available | Available | Available | Available | Available | ||

| Knock Pin Holes in Housing | Available | Available | Available | Available | Available | Available | ||

| Different Input/Output Shaft Configuration | Available | Available | Available | Available | Available | Available | ||

Special: Contact for further details.