Welding positioner

(Cantilever-mounted 2-axis type)

(Cantilever-mounted 2-axis type)

SPT Series(2 models)

| SPT02 | SPT06 |

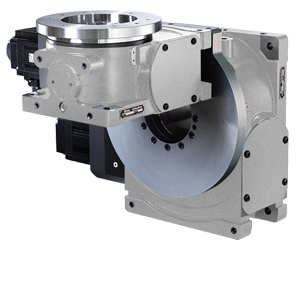

The thin welding positioner body enables a compact overall system configuration.

The large-diameter hollow bore makes wiring and line installation easy.

The cam mechanism creates outstanding settling performance,

and provides the rigidity needed to withstand emergency stops.

and provides the rigidity needed to withstand emergency stops.

| Model | SPT02 | SPT06 | |||

| Tabletop type | Tabletop type | ||||

| Rotary axis | Tilting axis | Rotary axis | Tilting axis | ||

| Output table diameter | mm | 155 | - | 155 | - |

| Output hollow diameter | mm | 120 | 118 | 120 | 170 |

| Allowable payload | kg | 200 | - | 600 | - |

| Allowable moment load*1 | N・m | 1,095 | 1,395 | 1,795 | 6,925 |

| Gear ratio | 140 | 140 | 140 | 120 | |

| Rotation angle | deg | 0 to 360 | ±135 | 0 to 360 | ±135 |

| Maximum rotating speed | min-1 | 30 (1sec/180deg) |

30 (0.5sec/90deg) |

30 (1sec/180deg) |

20 (0.75sec/90deg) |

| Repeatability | mm | ±0.03 (R=250mm) |

±0.03 (R=250mm) |

±0.03 (R=250mm) |

±0.03 (R=250mm) |

| Momentary max.allowable torque | N・m | 1,900 | 2,720 | 2,720 | 6,900 |

| Start / Stop limit torque | N・m | 875 | 1,095 | 1,350 | 1,675 |

| Internal moment of inertia at the input shaft*2 |

kg・m2 | 3.73×10−4 | 7.40×10−4 | 3.73×10−4 | 2.336×10−3 |

| Recommended motor power*3 | kW | 1kW | 1.5kW | 1.5kW | 2kW |

| Paint color | N1.5(Black) | N1.5(Black) | N1.5(Black) | N1.5(Black) | |

| Net weight | kg | 280 | 450 | ||

*1 The allowable moment load varies depending on the load weight.

Please refer to the allowable moment diagrams for more information.

*2 Internal moment of inertia at the input shaft depends on the SP attachment code. For details,

see the attachment code selection table on page 7 of the SP catalog.

*3 Recommended motor power value is reference only. It depends on the operating conditions.

Please refer to the allowable moment diagrams for more information.

*2 Internal moment of inertia at the input shaft depends on the SP attachment code. For details,

see the attachment code selection table on page 7 of the SP catalog.

*3 Recommended motor power value is reference only. It depends on the operating conditions.