Welding Positioners for Greater

Space-Savings and Higher Productivity

Space-Savings and Higher Productivity

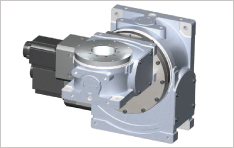

SP Series(6 models)

| SP030 | SP030H | SP060 |

| SP120 | SP240 | SP360 |

| SP120 | SP240 | SP360 |

Payload:300kg to 3,600kg

Large hollow bore:Φ245mm(SP360)

Thin-profile body:190mm(SP030 to SP060)

Repeatability:± 0.03mm(SP030 to SP120:R=250mm position)

Excellent stability and ensure shortening the takt time

Tough against impact from emergency stops

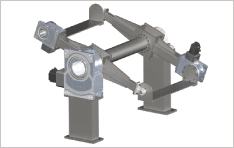

Cantilever-mounted 2-axis

welding positioner

welding positioner

BBQ welding positioner

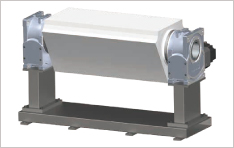

Horizontal single-axis

welding positioner

welding positioner

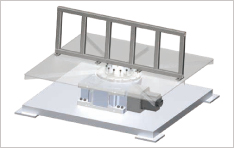

Ferris-wheel type

welding positioner

welding positioner

| Model | SP030 | SP030H | SP060 | SP120 | SP240 | SP360 | |

| Allowable payload | kg | 300 | 300 | 600 | 1,200 | 2,400 | 3,600 |

| Output table diameter | mm | 155 | 155 | 155 | 220 | 260 | 335 |

| Output hollow diameter | mm | 120 | 120 | 120 | 170 | 170 | 245 |

| Gear ratio | 140 | 56 | 140 | 120 | 126 | 168 | |

| Maximum rotating speed | min-1 | 30 (180°/sec) |

60 (360°/sec) |

30 (180°/sec) |

20 (120°/sec) |

20 (120°/sec) |

20 (120°/sec) |

| Repeatability | mm | ±0.03 (R=250mm) |

±0.03 (R=250mm) |

±0.03 (R=250mm) |

±0.03 (R=250mm) |

±0.05 (R=500mm) |

±0.05 (R=500mm) |

| Momentary max. allowable torque |

N・m | 1,900 | 1,160 | 2,720 | 6,900 | 9,400 | 12,700 |

| Start / Stop limit torque | N・m | 875 | 510 | 1,350 | 1,960 | 5,150 | 9,580 |

| Allowable moment load*1 | N・m | 1,095 | 850 | 1,795 | 7,360 | 10,800 | 15,100 |

| Internal moment of inertia at the input shaft*2 |

kg・m2 | 3.73×10-4 | 4.20×10-4 | 3.73×10-4 | 1.667×10-3 | 4.340×10-3 | 6.530×10-3 |

| Recommended motor capacity*3 |

kW | 1 | 1 | 1.5 | 2 | 5.5 | 7.5 |

| Paint color | N1.5 (Black) |

N1.5 (Black) |

N1.5 (Black) |

N1.5 (Black) |

N1.5 (Black) |

N1.5 (Black) |

|

| Net weight | kg | 120 | 120 | 120 | 270 | 545 | 780 |

*1 Allowable moment load depends on the mounting direction and payload.

For details, please refer to the allowable moment diagrams on pages 8 to 10.

*2 Internal moment of inertia at the input shaft depends on the attachment code.

For details, please refer to the attachment code selection table on page 7.

*3 Recommended motor capacity value is reference only. It depends on the operating conditions.

For details, please refer to the allowable moment diagrams on pages 8 to 10.

*2 Internal moment of inertia at the input shaft depends on the attachment code.

For details, please refer to the attachment code selection table on page 7.

*3 Recommended motor capacity value is reference only. It depends on the operating conditions.