SP10TV gives you high efficiency and

quality of welding.

SP10TV(1 model)

| SP10TV |

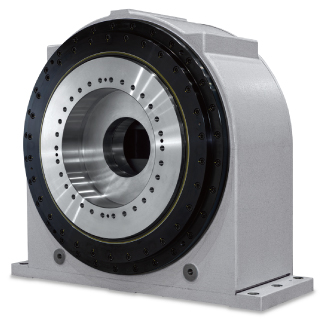

Enables positioning a large-heavy workpiece by using a heavy-load bearing.

Enables stable positioning by using a roller drive as driving unit.

The large-diameter hole (φ700, 365 mm) allows you to wire and piping, as well as install additional devices.

Simply maintenance by consolidating the maintenance window and

the grease ports to the back tide of the unit.

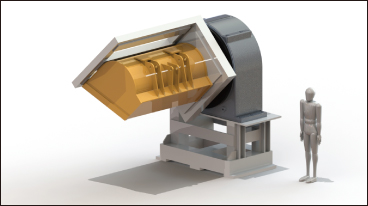

Cantilever mounting, 1 axis:

Welding example showing a construction machine bucket

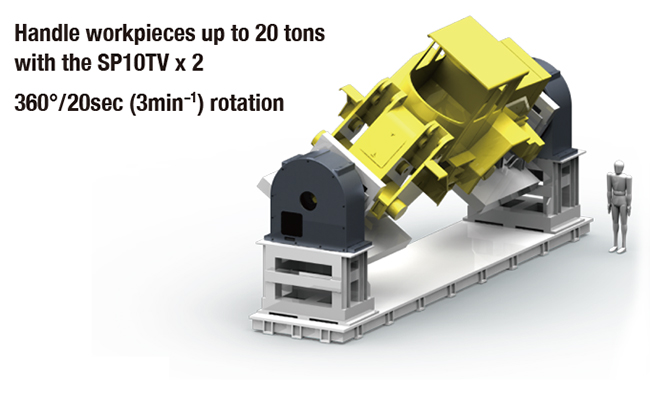

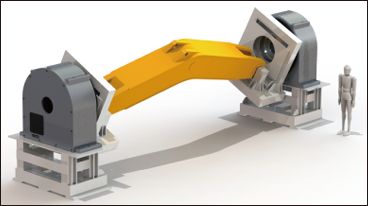

Double-sided mounting, 2-axis:

Welding example showing a construction machine boom

| Model | SP10TV | |

| Allowable payload | kg | 10,000 |

| Output table diameter | mm | 1080 |

| Output hollow diameter | mm | 365 |

| Gear ratio | 1134 | |

| Maximum rotating speed | min-1 | 3.0(18°/sec) |

| Repeatability | mm | ±0.5(R=500mm) |

| Momentary max. allowable torque | N・m | 25,380 |

| Start/Stop limit torque | N・m | 11,300 |

| Allowable moment load*1 | N・m | 150,000 |

| Internal moment of inertia at the input shaft*2 | kg・m2 | 1.15×10−3 |

| Net weight | kg | 5,850 |

*1 Allowable moment load depends on the mounting direction and payload. For details, please refer to the allowable moment diagrams.

*2 Internal moment of inertia at the input shaft depends on the attachment code. For details, please refer to the attachment code selection table on page 3.

*2 Internal moment of inertia at the input shaft depends on the attachment code. For details, please refer to the attachment code selection table on page 3.