The Ultimate NC Circular Table

Zero-backlash Technology Delivers Unsurpassed "Motion"

The RollerDrive CNC is a circular table designed to meet the requirements of machine tool manufacturers for greater speed and accuracy. The RollerDrive CNC uses Sankyo's zero-backlash reducer, the RollerDrive to deliver output motion unaffected by external disturbances, unlike gearmotors or torque motors.

The high accuracy and rigidity afforded by the zero-backlash technology gives the RollerDrive CNC its high rotary positioning accuracy of 10 seconds maximum, and the ability to hold up to heavy cutting of hard steel.

The high accuracy and rigidity afforded by the zero-backlash technology gives the RollerDrive CNC its high rotary positioning accuracy of 10 seconds maximum, and the ability to hold up to heavy cutting of hard steel.

No Clamping Required

Because the RollerDrive CNC does not have any structural play, it will hold steady without clamping. This construction not only reduces clamp/unclamp time, it consumes no energy, unlike conventional hydraulic systems. The combined benefits of a motion inherently free of play and clamping, allows positioning at maximum speeds for greater productivity.

For instance, the RollerDrive CNC can rotate and index 90° in less than 0.4 seconds.

For instance, the RollerDrive CNC can rotate and index 90° in less than 0.4 seconds.

Lifelong Accuracy

The RollerDrive CNC uses Sankyo's RollerDrive mechanism for excellent durability with little or no internal part wear, and no loss of accuracy over long-term use. Regular inspections and adjustments are not necessary.

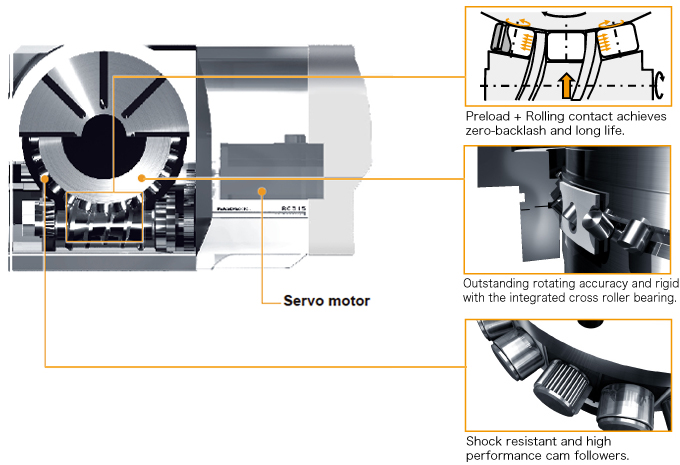

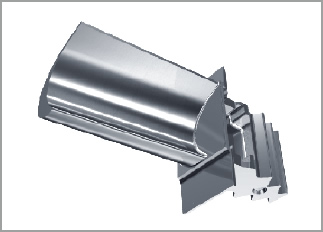

Mechanism

What is Zero-backlash Technology?

The RollerDrive mechanism consists of an input shaft formed like a screw, and an output turret with radially planted roller followers. The turret is formed into a cross roller bearing that minimizes runout of the output.

The roller followers are preloaded against the wedge-shaped ribs on the input shaft. Preload is adjusted with an adjustment mechanism on the input shaft that completely eliminates backlash. The figure on the right shows how zero backlash ensures superior accuracy in either direction of rotation (clockwise or counterclockwise).

By using needle bearings as the transfer element in the cross rollers, power transfers by rolling contact even under preload, unlike slipping contact. This ensures an efficiency of at least 90%, while achieving wear-free durability throughout the life of the unit.

All parts are made of steel alloy and produced at our state-of-the art facilities.

The roller followers are preloaded against the wedge-shaped ribs on the input shaft. Preload is adjusted with an adjustment mechanism on the input shaft that completely eliminates backlash. The figure on the right shows how zero backlash ensures superior accuracy in either direction of rotation (clockwise or counterclockwise).

By using needle bearings as the transfer element in the cross rollers, power transfers by rolling contact even under preload, unlike slipping contact. This ensures an efficiency of at least 90%, while achieving wear-free durability throughout the life of the unit.

All parts are made of steel alloy and produced at our state-of-the art facilities.

The Sign of Performance

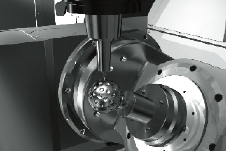

Competitive Edge for End Users

RollerDrive products find wide application in industrial fields where the highest level of performance is required. The machine tool industry is no exception. Some of the world's best known machine tool manufacturers make use of our RollerDrive technology. The RollerDrive QUALITY logo shown here tells users that their machining center is equipped with a rotary axis that offers the highest level of performance and quality in terms of speed, accuracy, and mechanical rigidity, even under heavy cutting loads. Machine manufacturers may display this logo on products that are embedded with the RollerDrive to differentiate their product in the market.

Contact Sankyo for more information about the use of this logo.

Contact Sankyo for more information about the use of this logo.

Applications

Tool sharpening: Precision improved by continuous zero backlash machining.

Automotive parts: High-speed positioning at 0.4 sec/90° slashes non-cutting time.

Mirror cylinders and molds: Continuous precision cutting at high speeds.

Turbine blade: Fast-accelerated driven machining.

Health care materials: Compact 5-axis system

![[RC] Durable, multi-feature model (may be used in the upright or horizontal position)](img/cnc01_ph04.jpg)

![[RS] Compact, high-speed type (exclusively for use in upright position)](img/cnc01_ph05.jpg)

![[RT] Compact, tilt type](img/cnc01_ph06.jpg)