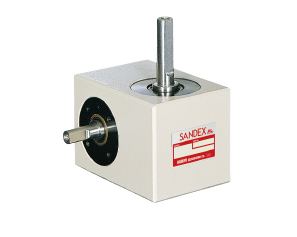

Employs a newly developed, high-precision, ultra-small, special cam follower, we were able to make the housing much more compact.

Wide Product Lineup

Available in many sizes and indexing configurations.

High Speed

High speed input (700 rpm)

High Efficiency

Low frictional torque reduces hysteresis loss.

Flexible Mounting Positions

Index mounts in any position with gearmotor mounting on either side of the index.

D, MI Series Specifications

| Description | Unit | 2.8D/E | 3.8D/E | 7MI |

| D - Indexing Stops | 2、3、4、6、8、10 | 2、3、4、5、6、8、10、12 | 8、10、12、16、20、24、32、40、48、60、72、80、96、120 | |

| E - Oscillating Angle | deg | 5、10、15、20、25、30、35、 40、45、50、55、60、65、 70、75、80、85、90 |

- | |

| Input Speed | rpm | 0 to 500(E type 0 to 400) | 0 to 500 | |

| Cam Curve | SMS-3、SMT-3、SMCV-3 | |||

| Output Allowable Thrust Load | N | 245 | 490 | 980 |

| Output Allowable Radial Load | N | 245 | 490 | 980 |

| Output Static Torque | N・m | Refer to Torque Capacity Table | ||

| Output Torsional Rigidity | N・m/rad | 800 | 2900 | 20000 |

| Output Moment of Inertia | kg・m2 | 5×10-6 | 1.2×10-4 | 2×10-3 |

| Output Allowable Bending Moment | N・m | 3.7 | 16 | 89 |

| Input Allowable Thrust Load | N | 196 | 343 | 343 |

| Input Max Repetitious Bending Force | N | 196 | 343 | 343 |

| Input Max Repetitious Allowable Torque | N・m | 7.84 | 24.5 | 24.5 |

| Input Torsional Rigidity | N・m/rad | 380 | 1600 | 1300 |

| Input Moment of Inertia(Note 1) | kg・m2 | 3.75×10-5 | 1.65×10-4 | 4.5×10-4 |

| Indexing Accuracy (1 Dwell) | sec | ±72 | ±72 | ±72 |

| Indexing Accuracy (2 Dwell) | sec | - | - | ±144 |

| Indexing Accuracy (3 Dwell) | sec | - | - | ±216 |

| Indexing Accuracy (4 Dwell) | sec | - | - | ±288 |

| Indexing Accuracy (5 Dwell) | sec | - | - | ±360 |

| Repeatability | sec | 36 | 36 | 36 |

| Product Weight | kg | 1.25 | 3.6 | 10 |

| Housing Color | Emerite satin | |||

Note 1) Input moment of inertia: J is calculated in dwell.

2.8D Rated Dynamic Output Torque

[Unit: N・m]

| S\θ | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 |

| 2 | 0.8 | 0.8 | ||||||

| 3 | 1.0 | 1.0 | 2.3 | 2.3 | 2.3 | |||

| 4 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | |||

| 6 | 1.3 | 3.2 | 3.1 | 3.1 | 3.0 | 3.0 | 2.9 | 2.8 |

| 8 | 1.7 | 1.7 | 1.6 | 1.6 | 3.6 | 3.5 | 3.4 | 3.3 |

| 10 | 1.9 | 1.8 | 1.7 | 1.7 | 1.6 | 1.6 | 1.5 |

3.8D Rated Dynamic Output Torque

[Unit: N・m]

| S\θ | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 |

| 2 | 2.3 | 2.3 | ||||||

| 3 | 2.8 | 2.8 | 5.6 | 5.6 | 5.6 | |||

| 4 | 3.4 | 3.4 | 3.3 | 3.3 | 3.2 | |||

| 6 | 4.4 | 4.4 | 4.4 | 4.3 | 4.3 | |||

| 8 | 3.8 | 7.7 | 7.7 | 9.0 | 8.8 | 8.6 | 8.5 | 8.3 |

| 12 | 4.7 | 4.6 | 4.4 | 9.3 | 9.1 | 8.9 | 8.7 | 8.5 |

| 16 | 6.1 | 6.0 | 5.8 | 5.7 | 5.5 | 5.4 | 5.2 | 5.1 |

| 24 | 2.9 | 7.0 | 6.9 | 6.7 | 6.5 | 6.3 | 6.1 | 6.0 |

7MI Rated Dynamic Output Torque

[Unit: N・m]

| S\θ | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 |

| 8 | 9.7 | 9.7 | 18.2 | 18.0 | 17.7 | 17.4 | 17.1 | |

| 10 | 11.2 | 11.1 | 10.9 | 10.6 | 10.4 | 10.2 | 10.0 | |

| 12 | 24.9 | 24.8 | 24.3 | 23.7 | 23.1 | 22.5 | 21.9 | 21.4 |

| 16 | 24.9 | 24.2 | 23.3 | 22.5 | 21.8 | 21.1 | 20.5 | 19.9 |

| 20 | 14.9 | 14.2 | 13.6 | 13.0 | 12.6 | 12.1 | 11.8 | 11.4 |

| 24 | 17.2 | 16.5 | 15.7 | 15.1 | 14.5 | 14.0 | 13.6 | 13.2 |

| 32 | 30.7 | 29.8 | 28.7 | 27.7 | 26.8 | 25.9 | 25.2 | 24.5 |

| 40 | 18.3 | 17.5 | 16.7 | 16.1 | 15.5 | 14.9 | 14.5 | 14.1 |

| 48 | 21.2 | 20.3 | 19.4 | 18.6 | 17.9 | 17.3 | 16.7 | 16.3 |

| 60 | 18.7 | 17.9 | 17.2 | 16.5 | 16.0 | 15.5 | 15.0 | |

| 72 | 21.7 | 20.7 | 19.9 | 19.1 | 18.5 | 17.9 | 17.4 | |

| 80 | 18.7 | 17.9 | 17.2 | 16.5 | 16.0 | 15.5 | 15.0 | |

| 96 | 21.7 | 20.7 | 19.9 | 19.1 | 18.5 | 17.9 | 17.4 | |

| 120 | 21.7 | 20.7 | 19.9 | 19.1 | 18.5 | 17.9 | 17.4 |