From the earliest worm gear mechanism to an age of

rapidly rolling mechanisms using roller gear cams

In 1973, Sankyo Seisakusho developed the first-in-Japan rotary positioning indexing driver. Its core technology is based on a roller gear cam mechanism.

This very reliable mechanism, with its complete elimination of backlash, its high-speed response, rigidity, high torque output, etc., is now being incorporated into our main product, RollerDrive, a major component at the heart of automatic machinery. It has gained tremendous trust and appreciation from customers everywhere.

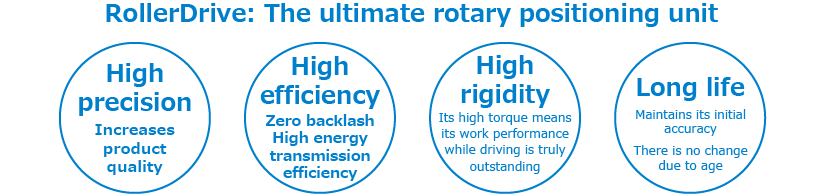

Our RollerDrive is the ultimate high performance rotary positioning unit. It uses a roller gear cam mechanism for excellent precision, rigidity, and durability.

Roller drives replace the trapezoidal screw in a linear system with a roller gear cam mechanism that provides great rigidity and high torque with good transmission efficiency, to perform positioning in a rotating system.

Our uniquely developed mechanism provides precision motion that maximizes a servo's control performance. The RollerDrive is greatly appreciated because it is a reliable component for rotary positioning on machine tools that require constant high precision.

Sankyo Seisakusho has a wide array of product variations for each type of application, including high-speed motion, high-precision positioning, high-torque for driving heavy loads, and great rigidity to improve processing quality. We manufacture products to meet individual customer needs.

Our RollerDrive is employed in a wide variety of fields: for positioning the working axis on machines, in edge grinders for LC glass substrates, large glass substrate transfer robots, large welding positioners for automobiles, automatic followers for solar power generation panels, and LED sorters.

It is especially highly evaluated for high-precision positioning of rotary cores used by major Japanese machine tool manufacturers.

■Examples of use

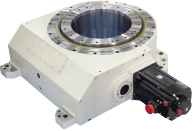

RA Series

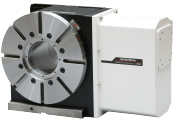

RU Series

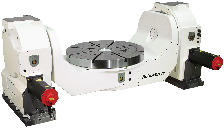

RW Series

RCD Series

RT Series

RTA1000 Series