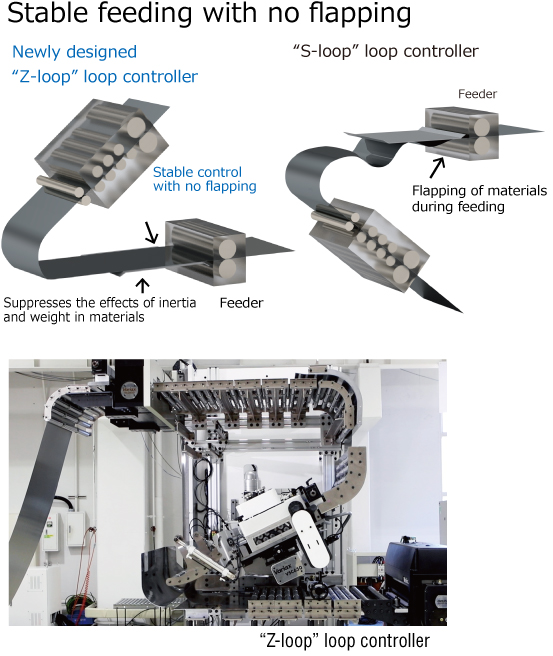

The NC Loop Controller is a unique product developed to condition loop stock for material feeding by restricting the material's freedom of motion. No other device works the same way. Servomotors control the amount of rotation of the drive rolls while sensors and our dedicated servo controller stabilizes the loop into an optimum shape. This reduces flapping in all speed ranges. The material is delivered to the feeder without scratches, creases, or markings, thus improving the quality of the finished product and the productivity of the line. Small footprint design makes it easy to install.

Excellent Stability

Keeps material from flapping when fed at high-speeds.

Maintains material in an optimized loop.

Maintains material in an optimized loop.

Easy to Adjust

Offers a touchpanel display for easy modification of feed parameters.

Also Performs Leveling (VSC Series only)

Straightens kinks and winding tendencies in material.

VSC Series General Specifications

| VSC70 | VSC150 | VSC400 | VSC650 | ||

| Feed Pitch | mm | 0~999 | 1~999 | ||

| Material Thickness | mm | 0.2~1.0 | 0.15~0.5 | ||

| Material Width | mm | max.70 | max.200 | 150~450 | 150~650 |

| Grip Force | N | 350*1 | 700*1 | 1,700*1 | 1,700*1 |

| Max. Feeding Speed | min-1 | 100 | 120 | ||

| Operating air pressure | m/min | 0.4~0.5 | |||

| Product weight | kPa | 320 | 350 | 3,800 | 3,850 |

| *1 | Listed grip forces above are correct with a pneumatic pressure of 0.4MPa |

| *2 | A Z-type loop is used |

VLC Series General Specifications

| VLC50 | VLC200 | VLC450 | VLC650 | ||

| Feed Pitch | mm | 0~999 | 1~999 | ||

| Material Thickness | mm | 0.2~1.0 | 0.15~0.5 | ||

| Material Width | mm | max.50 | max.200 | 150~450 | 150~650 |

| Grip Force | N | 350*1 | 1,500*1 | 4,000*1 | 4,000*1 |

| Max. Feeding Speed | min-1 | 150 | 100 | 120 | |

| Operating air pressure | m/min | 0.4~0.5 | |||

| Product weight | kPa | 250 | 285 | 3,680 | 3,730 |

| *1 | Listed grip forces above are correct with a pneumatic pressure of 0.4MPa |

| *2 | A Z-type loop is used |

>> OPUS1 Series

High-performance

servo feeder for

stamping presses

servo feeder for

stamping presses

>> OPUS2 Series

Servo feeder ideal for stamping motor cores for home appliances

>> Servo-dex EVR1 Series

An indexing/skewing drive system for rotating the motor cores used for electric motors in automobiles.

>> Servo-dex EVR2 Series

An indexing/skewing drive system for rotating the motor cores used

for electric motors in home

electrical appliances.

>> VG Series

Press feeders

Functionality

Reliability

Functionality

Reliability

>> V Series

Coil feeders for presses

Long Seller

Advanced Functionality

Good Reliability

Long Seller

Advanced Functionality

Good Reliability